JWS has further progressed the function of MIZ series to develop the new hot water sterilization type RO system which anticipates new water quality standard.

ü£ü@Equipped with all-automatic hot water sterilization system

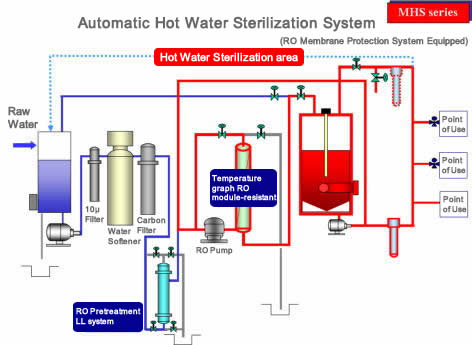

Equipped with all-automatic hot water sterilization system with heat resistant RO module.

In addition to RO module's sterilization, which was considered difficult in chemical sterilization, the periodical hot water sterilization is now possible in all RO lines.

ć@ From the start of sterilization to its completion, everything can be automatically controlled using the weekly timer.

ćASterilization area uses a two-selection method

ü@By allowing selection of the sterilization area, it can meet the cleansing schedule flexibly according to daily need

ü@ü╦A mode: RO tank + RO water supply line, B mode: RO membrane + RO tank + RO water supply line

ćBThrough interlocking operation with the dialysis equipment, it can sterilize until the branch pipe at the edge of supply water line.

ćCProperly control the rising temperature and the cooling temperature to protect RO membrane

1.ü@Since it does not use chemicals, it is very safe.

2.ü@Due to hot water's strong osmotic force, certain effects can be obtained.

3.ü@It can eliminate bacteria and viruses other than spores

4.ü@No need to worry about bacterial resistance

ü¢ A cited reference: Sterilization and disinfection guideline

ü£ü@RO water distribution method "D Cube System"

By controlling the water generation, distribution, stand-by operation depending on the RO water tank level, it always maintains a clean RO membrane surface. Meanwhile, in the distribution and stand-by operation, it can enhance the water quality for the pretreatment by placing back only the RO water to the raw water tank; therefore, it contributes to the enhancement of RO water quality.

ü£ü@PVDF piping

Adopted PVDF (polyvinylidene fluoride) is excellent with TOC interior smoothness, low elusion of metal ion, and biofilm.

Also, we have adopted a special welding method without any difference to grade in the joint area in order to eliminate retention portion.

ü£ü@Chemical sterilization system

By making the hot water sterilization a basic rule, it standardizes the semi-automatic sterilization system using chemicals after RO tank.

Patent Number 3128642 "Purification method of water production equipment for dialysis"

ü£ü@By making RO water tank a quadrangular pyramid shape

A complete automatic draining of retained water within RO tank can be done at night.üB

ü”By using the selection button, night time RO tank loop operation can be done as well.

ü£ü@RO water permutation within module

When transitioning to night-operation, inside RO module is exchanged with RO water.

ü£High performance touch panel

10 inch color LCD is used for the touch panel.

In addition to an improvement of operability and visibility, accumulation of various operational data has improved significantly. Moreover, operational condition management, input of set value, guidance, and memory functions are also further enhanced.

ü£All of them are equipped with inverter pump (Raw water pump/RO pump/water supply pump)

In RO pump, the slow start operation will soften the shock to the membrane and reduces the load to membrane surface.

Also, because it has an automatic flow rate adjustment function, there is the benefit of always being able to maintain the water generation amount at a constant width.

Moreover, in the water supply pump, by lowering the operation frequency at night, it saves night-time electricity and reduces circulation heat during loop operation.

ü£One-touch automatic bypass

The switchover operation between pretreatment bypass and RO bypass in case of emergency can be done by just pushing the button.

Also, the RO water desalination by raw water pump pressure is being standardized.

This will significantly contribute to lessening problems.

ü£Water leak detection system

To prepare for water leak, the switchover time of "only alarm / all stop" can be set at one's discretion.

| Model | MHS501 | MHS502 | MHS503 | MHS504 | |

| Permeation water volume(L/h) | Heating üi25üÄüjstandard/peak | 750/800 | 1500/1600 | 2100/2300 | 2800/3000 |

| RO Module (Main) | 8 inch heat resistance module | 1 | 2 | 3 | 4 |

| Necessary heat amount for raw water heating(kcalüj | éVüÄü©25üÄüi65% recovery rateüj | 22,200 | 44,400 | 63,700 | 83,100 |

| Raw water heating heater(kW) | 25 | 50 | 75 | 100 | |

| RO water sterilization heater(kW) | 30 | 40 | |||

| Pre-filter (mm x number of filter) | 10ā╩ | 750 x 1 | 750 x 3 | ||

| Active coal filter (mm x number of filter) | 750 x 3 | 750 x 5 | 750 x 8 | ||

| Softener resin volumeüiL) | 60 | 90 | |||

| Raw water tanküiL) | Total volume | 110 | 220 | ||

| Raw water pressurization pumpüikW) | Inverter control (2-step gear change) | 0.68 | 1.20 | 1.20 | 1.69 |

| RO pumpüikW) | Inverter control | 4 | 5.5 | 5.5 | |

| Water supply pumpüikW) | Inverter control (2-step gear change) | 0.38ü@éśü@2 | 0.38ü@éśü@2 | ||

| RO water tanküiL) | Full capacity quadrangular pyramid tank | 260 | 300 | ||

| Full capacity quadrangular pyramid tank(Wüj | Infiltration type | 60 | 60 | ||

| DimensionüiW x D x H) | 1,950x920x1,800 | 2,700x1,000x1,800 | |||

| Product weightüikg) | 1,030 | 1,060 | 1,560 | 1,630 | |

| Operating weightüikg) | 1,630 | 1,700 | 2,460 | 2,550 | |

| Power50/60Hz (kW) | 3āėü@200V üu75A ELBüv | 5.5 | 7.5 | 8.0 | |

| éPāėü@100V üu5A ELBüv | 1.0 | 1.0 | |||

| Connecting piping | Raw water inlet | 25A | 32A | ||

| Supply water outlet | 20Ax2 | 25Ax2 | |||

| Drain water outlet | 32Ax2 | 32Ax2 | |||

| Raw water heating method | Electric heater method, hot water direct introduction method, boiler circulation method, heat exchange method | ||||

| RO water sterilization heating method | Limited to electric heater | ||||

1.ü@The operating conditions of permeation water volume are 25üÄ water temperature, 0.8Mpa operating pressure, and 0.15% concentration of used raw water (NaCl).

2.ü@The time it can generate fresh water at "peak water volume" is up to 3 hours/day.

3.ü@The hardness of raw water is 55ppm as a design standard.

4.ü@The active coal filer uses 0.5ppm raw water effective chlorine as a design standard.

5.ü@Although the standard equipment recovery ratio is 65%, it may be lower depending on the amount of silica ion within the raw water.

6.ü@Due to this system's design, raw water heating is a must.

7.ü@The heater amount on the primary side can cover up to RO sterilization heater amount by raw water heating heater amount.

8.ü@Please prepare air conditioning and heat resistant drainpipes on the primary side.